VACUUM LIFTER SERIES GLASS

Barbaric glass lifting devices, with patented components, were developed in-house and in addition to particular operating convenience and unique safety standard. Glass elevating processes require stable, lightweight constructions with little net mass and flexible suction beams for all applications in glass transportation. Barbaric lifters are a functional unit of lifter and vacuum load sensing.

UniGlass Series

Our standard lifters for glass handling.

Our most frequently used lifting devices for glass handling. The Lifters of our UniGlass series are standard vacuum lifters for flat glass, insulated glass (IG) or windows with special safety measures.

Fields of application

For glass up to 3.3 x 2.5 m size and 250 kg weight.

Ideal for all processes with vertical processing:

- Vertical edging machines

- Vertical CNC machines

- Vertical washers

- Manipulation on A-frames

- Insulated glass lines

- Window production on vertical presses

- Window assembling

- and many more

Functions & Features

Narrow body for optimal view on the working area. Lifter with tilting device for glass and windows. For vertical lifting activities with different suction beams.

- Rotation range of 200°, electro-hydraulically

- Incl. safety system to protect against unintentional letting go of the glass due to incorrect operation

- Blow-off feature for quick release of glass

- Continous and smooth movements

- Electric chain hoist with wear-free magnetic brake

- Overload control with oil-lubricated slipping clut

- Emergency supply of the warning horn even in case of power failure

- Pneumatic vacuum generation using highly efficient ejector technology

- Ergonomic operating handle with all operating elements in the control handle

- Suction cups optimized for impression

Technical data

| Working load | 250 kg |

| Lifting speed | 0-10 m/min. |

| Rotation range | 200 ° |

| Rotation time | approx. 4 sec. / 90° |

| Suction time | approx. 2 sec. |

| Vacuum generation | Energy saving ejector |

| Usable chain length | 3 m |

| Dead weight | approx. 65 kg |

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application and glass thickness (details at the end of the page).

Also available with our safetyKit option.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Barbaric UniGlass Lifter UGL 2S // 250 kg // Special Version

Michael Oswald, our German sales representative, presents our UniGlass lifter UGL 2S at Glasstec 2022 in Germany.

Fields of application

For glass up to 3.3 x 2.5 m resp. up to 6 x 3.3 m with optional Y-slip beam and 500 kg weight.

Ideal for a wide range of applications:

- Horizontal and vertical glass processing machines

- Washing, grinding, curing, laminating or cutting in horizontal and vertical position

- Loading and unloading of autoclave cars

- and many more

Functions & Features

Handling device for all lifting activities in the glass, window or door production with different types of the suction beams. Very compact body for an optimal view on the working area.

- Rotating 200°, optional 360° endless

- Tilting function 90°

- Incl. safety system to protect against unintentional letting go of the glass due to incorrect operation

- Blow-off feature for quick release of glass sheets

- Continous and smooth movements (0 - 10 m/min.)

- Load beam with many variations depending on application and glass thickness

- Chain hoist overload safety feature

- Vacuum generation: pneumatically with safety function

- Special designs up to 2000 kg possible

Technical data

| Rotation Function | 200 °, rotation time approx. 6 sec./90° |

| Tilting Function | 90 °, tilting time approx. 6 sec./90° |

| Suction Cup Size | 270 mm or 350 mm |

| Chain Hoist | 250 kg: 0 - 10 m/min. 500 kg: 0 - 5 m/min. continuously variable speed (frequency converter) |

| Air Pressure | 6 - 8 bar filtered compressed air |

| Lifting Height | approx. 2 m |

| Operating Voltage | 230 V / 50 HZ |

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application and glass thickness (details at the end of the page).

Also available with our safetyKit option.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Michael Oswald, our German sales representative, presents our UniGlass lifter UGL 4 at Glasstec 2022 in Germany.

Functions & Features

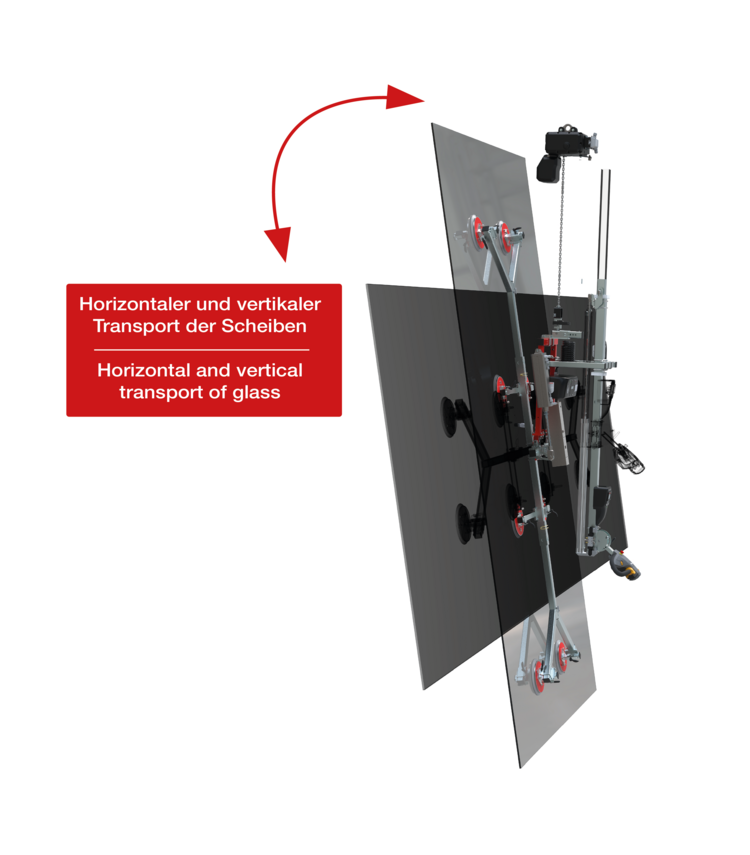

For use in grinding machines and in the production of photovoltaic elements.

Large and small glass can be removed from the grinding machine quickly and easily - both horizontally and vertically. The comfort handle is height-adjustable by up to 900 mm. Depending on the size of the glass, the height of the comfort handle can be adjusted electronically.

The specialized lifting device is suitable for flat glass up to 3.2 m x 2.5 m. The chain hoist, controlled by a frequency inverter, enables variable speeds from 0 to 10 m/min.

Thanks to the compact design, operators can work in close proximity to the product.

Max. working load 250 kg

Possible glass sizes:

- 0.8 m x 3.0 m

- 1.0 m x 1.0 m

- 2.3 m x 2.3 m

- 0.8 m x 2.0 m

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application and glass thickness (details at the end of the page).

Also available with our safetyKit option.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Fields of application

- Coating lines (suction on the uncoated side)

- Turning of glass for double-sided processing (furniture hadware fittings assembly)

- Printed glass - removal from the unprinted underside (special table required)

Horizontal tilting of parts by 180°

Functions & Features

- Tilting of parts 180° horizontally

- Continously variable tilting speed

- Complete solution with chain hoist, infinitely variable

- One-handed operation through ergonomic handle

- Manual adjustment of the center of gravity

- Vacuum is generated pneumatically by a venturi-nozzle (vacuum ejector)

Technical data

- Working load: 250 kg

- Tilting speed: approx. 6 sec./90°

- Suction cups: Ø 270 mm (other suction cups available according to requirements)

- Lifting speed: 0 - 10 m/min. continuously with frequency converter

- Operating voltage: 230 V / 50 Hz

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application and glass thickness (details at the end of the page).

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Your benefits at a glance

- vertical or horizontal transport of flat glass

- vacuum is generated pneumatically by a venturi nozzle

- for quick release of the glass plate a "push off equipment" is installed

- incl. chain hoist

- incl. security system, the glass can only be released after putting it down safety

- incl. comfort handle

- incl. beam with 4 suction cups BA 270

- maximum load 250 kg or 500 kg

Do you need more information or would you like a quote?

Technical data

| Suction Cup Size | 270 mm or 350 mm |

| Chain Hoist: | 250 kg: 0 - 10 m/min. 500 kg: 0 - 5 m/min. continously variable speed (frequency converter) |

| Air Pressure | 4 - 8 bar filtered compressed air |

| Lifting Height | approx. 2 m |

| Operating Voltage | 230 V / 50 HZ |

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application and glass thickness (details at the end of the page).

Also available with our safetyKit option.

Technical changes and errors excepted.

Your benefits at a glance

- vertical transport of flat glass

- electro-hydraulic rotation mechanism for a rotation range of 200 ° vertically

- vacuum is generated pneumatically by a venturi nozzle

- for quick release of the glass plate a "push off equipment" is installed

- incl. chain hoist

- incl. security system, the glass can only be released after putting it down safety

- incl. comfort handle

- incl. beam with 4 suction cups BA 270

- maximum load 250 kg or 500 kg

Do you need more information or would you like a quote?

Technical data

| Tilt range | 200 ° |

| Suction Cup Size | 270 mm or 350 mm |

| Chain Hoist | 250 kg: 0 - 10 m/min. 500 kg: 0 - 5 m/min. continously variable speed (frequency converter) |

| Air Pressure | 4 - 8 bar filtered compressed air |

| Lifting Height | approx. 2 m |

| Operating Voltage | 230 V / 50 HZ |

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application and glass thickness (details at the end of the page).

Also available with our safetyKit option.

Technical changes and errors excepted.

Your benefits at a glance

- narrow main body design, ideally suited for picking up glass from vertical glass racks

- vertical transport of flat glass

- electro-hydraulic rotation mechanism for a rotation range of 100 °

- vacuum is generated pneumatically by a venturi nozzle

- for quick release of the glass plate a "push off equipment" is installed

- incl. chain hoist

- incl. security system, the glass can only be released after putting it down safety

- incl. comfort handle

- incl. beam with 4 suction cups BA 270

- maximum load 400 kg

Technical data

| Rotating Function | 100 ° |

| Suction Cup Size | 4x 270 mm |

| Chain Hoist | 0 - 10 m/min. continuously variable speed (frequency converter) |

| Air Pressure | 4 - 8 bar filtered compressed air |

| Operating Voltage | 230 V / 50 HZ |

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Your benefits at a glance

- vertical and horizontal transport of flat glass

- pneumatic tilt device for a tilting range of 90°

- vacuum is generated pneumatically by a venturi nozzle

- quick release of the glass plate through "push off equipment"

- incl. Chain hoist

- incl. security system, the glass can only be released after putting it down safety

- incl. Comfort handle

- incl. beam with 4 suction cups BA 270

- working loads 250 kg or 500 kg

Do you need more information or would you like a quote?

Technical data

| Tilting Function | 90 ° |

| Suction Cup Size | 270 mm or 350 mm |

| Chain Hoist | 250 kg: 0 - 10 m/min. 500 kg: 0 - 5 m/min. continously variable speed (frequency converter) |

| Air Pressure | 6 - 8 bar iltered compressed air |

| Lifting Height | approx. 2 m |

| Operating Voltage | 230 V / 50 HZ |

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application and glass thickness (details at the end of the page).

Also available with our safetyKit option.

Technical changes and errors excepted.

Vacuum lifter UGL 4E with electric vacuum pump for mobile use without compressed air connection

Your benefits at a glance

A very compact body allows an easy view to the glass. For safe working loads from 150 kg to 2000 kg with different body types.

- Incl. security system, the glass can only be released after putting it down safety

- continuous lifting

- tilting 90°

- rotating 200°, optional 360° endless

- beams with various variation possibilities depending on application and glass thickness

- overload control

Do you need more information or would you like a quote?

Technical data

| Rotation Function | 200 °, rotation time approx. 6 sec./90° |

| Tilting Function | 90 °, tilting time approx. 6 sec./90° |

| Suction Cup Size | 420 mm, Safety system with dual circuit monitoring |

| Chain Hoist | 250 kg: 0 - 10 m/min. 500 kg: 0 - 5 m/min. continuously variable speed (frequency converter) |

| Air Pressure | 4 - 8 bar filtered compressed air |

| Lifting Height | approx. 2 m |

| Operating Voltage |

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application and glass thickness (details at the end of the page).

Also available with our safetyKit option.

Technical changes and errors excepted.

Glass MiniLifter GML

fast - compact - safe

Unique handling solution for quick manipulation of parts with flat surfaces.

Functions and Features

Unique handling solution for quick manipulation of parts with flat surfaces. Designed for all quick handling processes in glass and window production. Ergonomic construction with handles on both sides of the frame. One-handed operation with continuous lifting mechanism. All operating elements are integrated in the compact body

Technical data

- Working load: up to 150 kg

- Suction cups: Ø 270 mm or 350 mm

- Vacuum generation: pneumatically with safety function

- Lifting speed: up to 20 m/min. regulated continuously

- Suction time: approx. 2 sec.

- Release time: approx. 1 sec.

- 360° (endless) rotation function at model GML 2

Technical changes and errors excepted.

Do you need more information or would you like a quote?

All advantages at a glance

- Lightweight material handling by small construction and low weight

- Interchangeable suction cups, tested and durable rubber material with minimum suction cup prints

- High safety standard with pneumatic vacuum generation and secured release function

- Overload protection on the chain hoist

- Safety signal-horn and vacuum gauge integrated in the base body

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application and glass thickness (details at the end of the page).

Also available with our safetyKit option.

Functions and Features

Unique handling solution for quick manipulation of parts with flat surfaces. Designed for all quick handling processes in glass and window production. Ergonomic construction with handles on both sides of the frame. One-handed operation with continuous lifting mechanism. All operating elements are integrated in the compact body

Technical data

- Working load: up to 150 kg

- Suction cups: Ø 270 mm or 350 mm

- Vacuum generation: pneumatically with safety function

- Lifting speed: up to 20 m/min. regulated continuously

- Suction time: approx. 2 sec.

- Release time: approx. 1 sec.

- 360° (endless) rotation function at model GML 2

Technical changes and errors excepted.

Do you need more information or would you like a quote?

All advantages at a glance

- Lightweight material handling by small construction and low weight

- Interchangeable suction cups, tested and durable rubber material with minimum suction cup prints

- High safety standard with pneumatic vacuum generation and secured release function

- Overload protection on the chain hoist

- Safety signal-horn and vacuum gauge integrated in the base body

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application and glass thickness (details at the end of the page).

Also available with our safetyKit option.

Energy-Saving Function of our vacuum lifters

In this video Florian Barbaric is explaining our Energy-Saving Function of our vacuum lifters in combination with our SafetyKit safety control. Not only can we preserve resources due to this function, it also saves owners a substantial amount of cost for the constant supply of air pressure that would otherwise be needed for lifting glasses with a conventional lifter.

- Most eco-friendly lifter series available

- Cost-effective shutoff of expensive pressure air supply

- Short ROI on optional SafetyKit upgrade including Eco-Mode

- Reduces overall noise level on production floor

This video was filmed during the international trade show for glass production “Glasstec 2022” in Düsseldorf Germany.

SafetyKit

An innovative Upgrade for your handling system

The safetyKit vastly increases user safety and adds a ton of other features to the handling system as well.

Main advantages at a glance:

- Maximum safety for the operator

- Pressure and vacuum monitoring

- Weight sensor for load control

- Eco-Mode (Compressed air saving function)

- Automatic test of suction performance

- Detailed error reports & statistical analysis

- Service and maintenance reminderss

Optional:

- Automatic suction start while approaching the glass

- Safe suction cup switch-off and automatic reduction of maximum weight

SafetyLifter Series

Safe glass handling made easy! Safety lifter series with integrated safety test.

The innovative safetyLifter series sets a new standard for high safety in glass plate handling, combining state-of-the-art safety features with maximum comfort for an effortless operation. An integrated self-test during system start-up checks the system for proper function ensures the highest level of reliability.

Your benefits at a glance

- narrow body for improved access to the workspace

- for vertical transport of flat glass

- working load 300 kg

Safety and Control

- Entire lifter control via touchscreen surface

- Obligatory safety test at start

- Visualized guide through the safety test

- Release after examination of the suction cups, vacuum generation, load and tightness

- Automatic logging of tests for internal audit. Query option of upscale weights, downtimes, cycle times or failure. Transmission optional via Wi-Fi.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Unique lifting functions

- Individual suction cups can be turned off temporarily and per each lifting procedure. The load capacity is automatically reduced.

- Lifting of horizontal glass without sufficient operating vacuum is stopped immediately.

- The actual lifting weight is displayed.

- If necessary, the use of support legs is required and controlled.

- The suspension point, and thus a steep position of the glass can be adjusted electrically.

- Through the registration of the currently raised glass weight the lifter can be controlled in all functional areas.

- The safe working load can be set separately between horizontal and vertical lifting. Under certain circumstances, a 250 kg vertical lifter can lift 500 kg in horizontal position. Since there is no slipping while horizontal lifting, the safety factor can be reduced.

Your benefits at a glance

- for vertical transport of flat glass 3,2 x 2,5 m

- rotation of 100°

- workling loads 300 kg or 500 kg

- endless rotation oprional

Safety and Control

- Entire lifter control via touchscreen surface

- Obligatory safety test at start

- Visualized guide through the safety test

- Release after examination of the suction cups, vacuum generation, load and tightness

- Automatic logging of tests for internal audit. Query option of upscale weights, downtimes, cycle times or failure. Transmission optional via Wi-Fi.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Unique lifting functions

- Individual suction cups can be turned off temporarily and per each lifting procedure. The load capacity is automatically reduced.

- Lifting of horizontal glass without sufficient operating vacuum is stopped immediately.

- The actual lifting weight is displayed.

- If necessary, the use of support legs is required and controlled.

- The suspension point, and thus a steep position of the glass can be adjusted electrically.

- Through the registration of the currently raised glass weight the lifter can be controlled in all functional areas.

- The safe working load can be set separately between horizontal and vertical lifting. Under certain circumstances, a 250 kg vertical lifter can lift 500 kg in horizontal position. Since there is no slipping while horizontal lifting, the safety factor can be reduced.

All benefits at a glance:

- narrow main body design, ideally suited for picking up glass from vertical glass racks

- electric tilting unit for 100° tilt range

- working load 400 kg

Safety and Control

- Entire lifter control via touchscreen surface

- Obligatory safety test at start

- Visualized guide through the safety test

- Release after examination of the suction cups, vacuum generation, load and tightness

- Automatic logging of tests for internal audit. Query option of upscale weights, downtimes, cycle times or failure. Transmission optional via Wi-Fi.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Unique lifting functions

- Individual suction cups can be turned off temporarily and per each lifting procedure. The load capacity is automatically reduced.

- Lifting of horizontal glass without sufficient operating vacuum is stopped immediately.

- The actual lifting weight is displayed.

- If necessary, the use of support legs is required and controlled.

- The suspension point, and thus a steep position of the glass can be adjusted electrically.

- Through the registration of the currently raised glass weight the lifter can be controlled in all functional areas.

- The safe working load can be set separately between horizontal and vertical lifting. Under certain circumstances, a 250 kg vertical lifter can lift 500 kg in horizontal position. Since there is no slipping while horizontal lifting, the safety factor can be reduced.

Your benefits at a glance

- for vertical transport of flat glass 3,2 x 2,5 m

- electric tilting unit for 90° tilt range

- workling loads 300 kg or 500 kg

Safety and Control

- Entire lifter control via touchscreen surface

- Obligatory safety test at start

- Visualized guide through the safety test

- Release after examination of the suction cups, vacuum generation, load and tightness

- Automatic logging of tests for internal audit. Query option of upscale weights, downtimes, cycle times or failure. Transmission optional via Wi-Fi.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Unique lifting functions

- Individual suction cups can be turned off temporarily and per each lifting procedure. The load capacity is automatically reduced.

- Lifting of horizontal glass without sufficient operating vacuum is stopped immediately.

- The actual lifting weight is displayed.

- If necessary, the use of support legs is required and controlled.

- The suspension point, and thus a steep position of the glass can be adjusted electrically.

- Through the registration of the currently raised glass weight the lifter can be controlled in all functional areas.

- The safe working load can be set separately between horizontal and vertical lifting. Under certain circumstances, a 250 kg vertical lifter can lift 500 kg in horizontal position. Since there is no slipping while horizontal lifting, the safety factor can be reduced.

Your benefits at a glance

- for vertical and horizontal transport of flat glass 3,2 x 2,5 m

- rotation range of 100°

- electric tilting unit for 90° tilt range

- workling loads 300 kg or 500 kg

- endless rotation oprional

Safety and Control

- Entire lifter control via touchscreen surface

- Obligatory safety test at start

- Visualized guide through the safety test

- Release after examination of the suction cups, vacuum generation, load and tightness

- Automatic logging of tests for internal audit. Query option of upscale weights, downtimes, cycle times or failure. Transmission optional via Wi-Fi.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Unique lifting functions

- Individual suction cups can be turned off temporarily and per each lifting procedure. The load capacity is automatically reduced.

- Lifting of horizontal glass without sufficient operating vacuum is stopped immediately.

- The actual lifting weight is displayed.

- If necessary, the use of support legs is required and controlled.

- The suspension point, and thus a steep position of the glass can be adjusted electrically.

- Through the registration of the currently raised glass weight the lifter can be controlled in all functional areas.

- The safe working load can be set separately between horizontal and vertical lifting. Under certain circumstances, a 250 kg vertical lifter can lift 500 kg in horizontal position. Since there is no slipping while horizontal lifting, the safety factor can be reduced.

ISO GlassLifter IGL

Individual lifting solutions for lifting processes in ISO glass production.

For vertical transport of insulating glass (IG-glass) up to 6 x 3 m with support feet to prevent the discs from slipping.

For working loads up to 2100 kg.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Characteristics

Hydraulic support legs with electrically adjustable glass support block for stabilising the glass during manipulation after sealing, including hydraulically adjustable suspension point for hooking into the customer's crane hook. The device can also be used without support feet for single panels.

Your benefits at a glance

- for the vertical transport of insulating glass (IG-glass) up to 6 x 3 m with suction cups on either side of the glass

- Special design for hanging on an overhead crane as well as on a truck-mounted crane

- Basic version with safety devices

- Available in battery or electrical version.

Technical changes and errors excepted.

The EasyLifter ISO is designed to work on battery power. It could not be easier to operate, and makes moving loads safe and problem-free. Two operating handles for easy manipulation are mounted on the construction. The only requirement is a solid material with smooth surfaces.

The adjustable support leg provides optimum support when transporting freshly glued insulating glass.

Do you need more information or would you like a quote?

Technical data

- Safe working load: ,max. 150 kg each suction cup

- Suction cup: Ø 270 mm (changeable)

- Battery operation of up to 300 suction processes

- fast suction time approx. 2 sec

- vacuum monitoring system

- battery-powered vacuum pump

- Delivery with power supply unit (230 V)

- excellent carrying comfort

- lightweight construction – weight approx. 3 kg

Technical changes and errors excepted.

Special Lifters

Glass lifters for special applications

With the RGH Lifter series, we offer lifters with a rigidly guided load arm that enables precise pick-up and set-down as well as effortless and accurate movements under load.

Here you can see our RGH 2 glass lifter in use by one of our German customers (Engelhardt + Geissbauer GmbH), who uses the lifter to install windows and doors in walls for prefabricated houses. Since the delivery of this solution, an operator can effortlessly install windows and doors without further assistance, which at the same time brings a huge increase in productivity and ergonomics.

- Optimal for installing windows, glass or doors.

- Easy and convenient lifting of glass and windows weighing up to 350 kg

- Fast vacuum generation

- Allows effortless movement under load

- Extremely precise placement or installation possible

- Includes optional tilt function (precise movements possible)

- Optional rotation function (up to 360°)

Customer installation at Engelhardt + Geissbauer/Germany

RGH Glass Lifter Product innovation at the “Dach+Holz” in Stuttgart, Germany

Our sales Expert Markus Gruszka explains on our trade show booth, why the RGH Vacuum Lifter is such a big help for the production of prefabricated houses.

Barbaric is a strong partner for special handling solutions. Here is an example of a container loading aid, which was realised for our partner Internorm on customer request. With the SGH ContainerWinch, windows and other objects can be easily pulled out of containers and manipulated. The container loading aid is controlled via remote control and can be easily stowed away on the ceiling at any time.

- Simple loading aid for removing objects from containers

- Cable hook is attached to the object and the cable winch is switched on by remote control

- Simple control of the system via remote control, simultaneous load guidance possible

- Handling arm can be folded out and stowed away again at any time

- Easy pulling out of the rope possible by decoupling from the drive train

- Crane suspension enables movement / adjustment in all directions

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Lifting / Automatic Gripping / Rotation (180°) / 200 kg load

Handling bulky glass transport racks made easy - with our SGL GlassRackLifter. In order to simplify transport and storage, transport racks (also called A-frames) have to be manipulated and stacked. The SGL GlassRackLifter features an automatic pneumatic clamping mechanism, allowing safe and easy handling of transport racks and a 180° rotation for stacking on top of each other.

Do you need more information or would you like a quote?

Features

- Ideal for the handling racks and storing them on top of each other

- Manually adjustable traverse for flexible handling

- Automatic gripping mechanism (pneumatic)

- Rotation of 180° with variable speed

- Fast and continuously variable lifting speeds

- Ergonomic handle with integrated controls

Technical changes and errors excepted.

Characteristics

- max. glass dimensions: 18.000 mm x 3.280 mm

- max. glass weight: 2.800 kg

- five independent vacuum circuits

- Balance settings (rotating, tilting)

- Motorised length adjustment

- retractable suction cups

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Special handling solution for curved glass up to 1000 kg. Due to the universal design convex or concave lenses can be accommodated. Thanks to the innovative radio remote control, effortless control is also possible from a distance.

Fields of application:

- Removal of glass from an oven

- Manipulation through the processing steps (tilting and rotation possible)

- Installation on-site (construction version with battery available)

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Special beams and suction traverses

We offer a suitable lifting beam for every application.

With 2 lockable suction cups (diameter 350 mm). The beam can also be delivered with 2 smaller suction cups (diameter 270 mm). The suction cups can be locked by spring bolt in 3 steps.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Also suitable for transporting windows and doors with glazing bars with adjustable distance between the beams.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Suitable for transporting windows and doors on the outer frame. The offset slide is equipped with a parallel guide.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Optional cross beam extension especially suitable for the stabilization of large and thin glass.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Crane- and craneway systems

Combining high performance with ease of use. Our crane systems are specifically designed and built for handling tasks.

Slewing crane systems in lightweight construction for all working loads and arm lengths. On request with enlarged mounting plate.

Also available for wall mounting.

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Lightweight craneway system with steel bridge for manual operation allows track gauges of up to 8 m. All trolleys with guide rollers on the side.

Do you need more information or would you like a quote?

Case studies

Ideas that move!

Learn more about our realized customer projects.

Our sales team is there for you!

If you have any questions or would like a quote, please contact us.

Phone: +43 732 779800

Email: sales-manual@barbaric.at

After-Sales-Service

We are there for you - even years after the sale.

In order to ensure that our handling systems function optimally, we rely on good cooperation with our customers and particularly customer-oriented support through our competent service team.

Our products

Manual vacuum lifters from Barbaric enable efficient handling of heavy wood and glass panels and save valuable time in production. While conventional manipulation by hand requires 2-3 employees, a vacuum lifting systems allows a single employee to move oversized panels with maximum ergonomics and without physical exertion.

Product overview Manual lifters

Our automatic handling solutions take over fully automated process steps in wood panel and part production. Panel storage and retrieval systems, feeding systems, buffer storage and return systems are just a few examples of modern systems in the field of material handling. All of our machines are built individually according to the requirements of our customers, while proven handling concepts and trusted components are used.