Return systems

Our goal is to optimize workflow in the area of edgebanding machines. Our „Return-series“ products convince customers with excellent price-performance ratio and an intelligent design. The in-house development of many components allows us to create ergonomic systems with high profitability and short payback times. Through years of expierience and a special know-how in handling technology we create systems with a special attention to speed, design and durability.

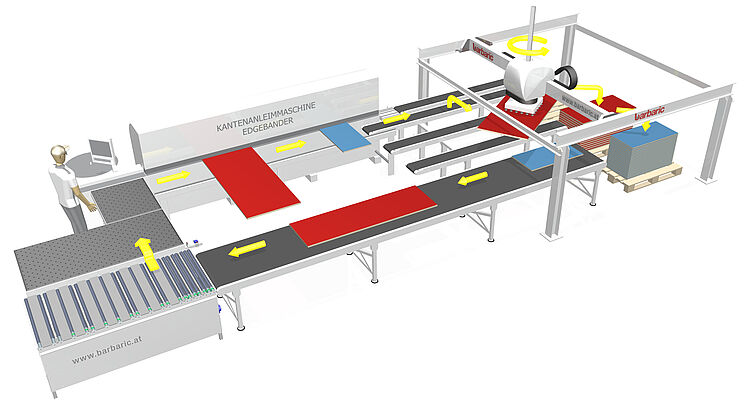

Connection to edgebanding machine

The RTS compact is a standalone system that can be independently connected to any edgebander regardless of the brand. The throughput speed can be continously adjusted to match the edgebander speed. The RTS 04 is shipped as a complete package including a control cabinet and is ready for operation immediately after installation.

Optionally with „Extension Conveyor Technology RTS Compact“ for easy turning of parts during transverse edging.

Can be optionally equipped with the „Ergonomics Package RTS Compact“. A lifting table and an air cushion table are used at the end of the return conveyor. This option enables ergonomic working.

Your benefits at a glance

- connectable with edgebanders of all manufacturers

- one-man operation of the edgebander possible

- highest level of ergonomics

- savings in personnel costs

- careful material transport

- installation time approx. 0,5 days

- rotation device for small parts

Technical changes and errors excepted.

Our German sales representative Dennis Fuhrmann demonstrates our Return System RTS Compact at Ligna 2023 in Hannover.

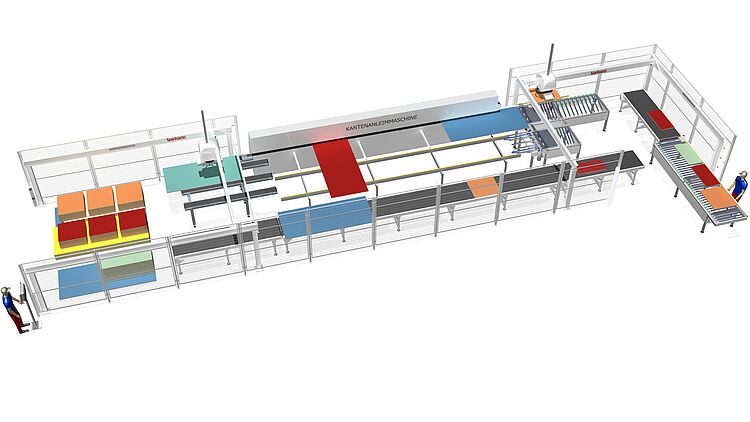

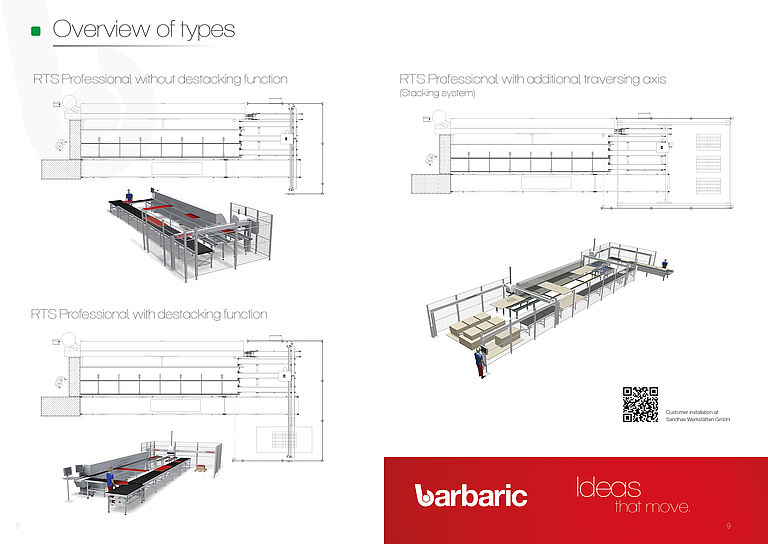

Modular and customer-specific production

Through our intelligent and modular product design we can assemble an individual and ideal solution for fast handling at the edgebander. Installation and start-up of the RTS Professional is quick and easy as all components come preassembled.

Characteristics

By integrating the RTS Professional into production lines, material flow and machine utilization are optimized. Versatile, customer-specific solutions can be realized.

Destacking function

Depending on the design of the machine, several stacking stations can be defined. The software also allows formation of interlocked layers for serial parts. Further, lifting tables can be implemented to increase performance.

Dual mode

Our machine also features „dual mode“ in which the machine picks up two parts at simultaneously to maximize throughput. The operator decides if the parts should be stacked or returned.

Your benefits at a glance

- gentle manipulation, through vacuum suction technology, no more material damages

- flexible in the part size

- adaptation to the space conditions

- reduced personnel costs

- simplification and alleviation of production processes

- higher machine utilization

- highest flexibility in the production process

- connectable with edgebanders of all manufacturers

- retrofitting with existing edgebanders possible

- self-programmable and flexibly expandable stacking spots

- payback times of less than one year

- fully automated handling of parts

- 90° / 180° turning function

- installation time approx. 2 days

Technical changes and errors excepted.

Customer installation at Sandhas Werkstätten GmbH

We present our RTS Professional with a Homag edge banding machine which is installed at our customer Sandhas Werkstätten in Calw, Germany. Production Manager Aaron Sandhas and our Sales Manager Martin Kress talk about their experiences with Barbaric GmbH and the advantages of the RTS Professional.

That makes the difference

The manipulator for the RTS Industrial was designed for use in industrial environments. Loads of 100 kg as well as parts up to 4100 mm in length characterize this type of return system.

Characteristics

- Connectable to edgebanders of all manufacturers

- 90° / 180° turning function

- One-man operation of the edgebander possible

- Highest level of ergonomics

- Savings in personnel costs

- Careful material transport

- Industrial version of the manipulator

- Optional stacking of finished parts on pallet or conveyor belt possible

Data interface

We offer standardized data interfaces to well-known manufacturers of edge banding machines as well as to control systems. By scanning the parts before processing, all part-specific information is retrieved. The system thus operates fully automatically without any operator intervention.

Your benefits at a glance

- gentle manipulation, through vacuum suction technology, no more material damages

- flexible in the part size

- adaptation to the space conditions

- reduced personnel costs

- simplification and alleviation of production processes

- higher machine utilization

- highest flexibility in the production process

- connectable with edgebanders of all manufacturers

- retrofitting with existing edgebanders possible

- self-programmable and flexibly expandable stacking spots

- payback times of less than one year

- fully automated handling of parts

Technical changes and errors excepted.

Characteristics

With the Return series from Barbaric, the return of edged parts is already completely standardized. On this basis, we implement fully automatic systems on throughfeed machines such as edge banders or drilling lines. Data connections can be realized individually and form the central control of the entire system.

Manipulators from the modular system

Our proven standard manipulators of the RTS Professional and RTS Industrial series form the basis for these machines and systems. Depending on the requirements, the manipulators are realized as simple gantries or as 3-dimensional stacking systems. The rotating function as well as a dynamic mode of operation complete the system.

Conveyor technology

Whether simple conveyor belts, roller conveyors or complex conveyors with lifting cross conveyor technology, we offer a wide range of solutions due to our in-house construction department. The speeds of the conveying elements go up to 70 m/min. to also offer an appropriate performance.

Your benefits at a glance

- gentle manipulation, through vacuum suction technology, no more material damages

- flexible in the part size

- adaptation to the space conditions

- reduced personnel costs

- simplification and alleviation of production processes

- higher machine utilization

- highest flexibility in the production process

- connectable with edgebanders of all manufacturers

- retrofitting with existing edgebanders possible

- self-programmable and flexibly expandable stacking spots

- payback times of less than one year

- fully automated handling of parts

Performance at an attractive price

Due to our experience in the field of automation and many standard components we can offer attractively priced solutions for craft and small industrial companies. An output of 1000 to 1200 parts per shift is possible.

Technical changes and errors excepted.

Our German sales representative Michael Klettenheimer presents our Return System RTS Professional at Ligna 2023 in Hannover.

Case studies

Ideas that move!

Learn more about our realized customer projects.

Our sales team is there for you!

If you have any questions or would like a quote, please contact us.

Phone: +43 732 779800

Email: sales-automatic@barbaric.at

Suitable handling concepts for rational production.

Even in the environment of smaller production machines, the necessity of well thought-out handling systems is hardly ever questioned. Fully automatic loading and unloading systems are being used more and more frequently not only in larger companies, where >>>

After-Sales-Service

We are there for you - even years after the sale.

In order to ensure that our handling systems function optimally, we rely on good cooperation with our customers and particularly customer-oriented support through our competent service team.

Our products

Manual vacuum lifters from Barbaric enable efficient handling of heavy wood and glass panels and save valuable time in production. While conventional manipulation by hand requires 2-3 employees, a vacuum lifting systems allows a single employee to move oversized panels with maximum ergonomics and without physical exertion.

Product overview Manual lifters

Our automatic handling solutions take over fully automated process steps in wood panel and part production. Panel storage and retrieval systems, feeding systems, buffer storage and return systems are just a few examples of modern systems in the field of material handling. All of our machines are built individually according to the requirements of our customers, while proven handling concepts and trusted components are used.