Horizontal Storage Systems

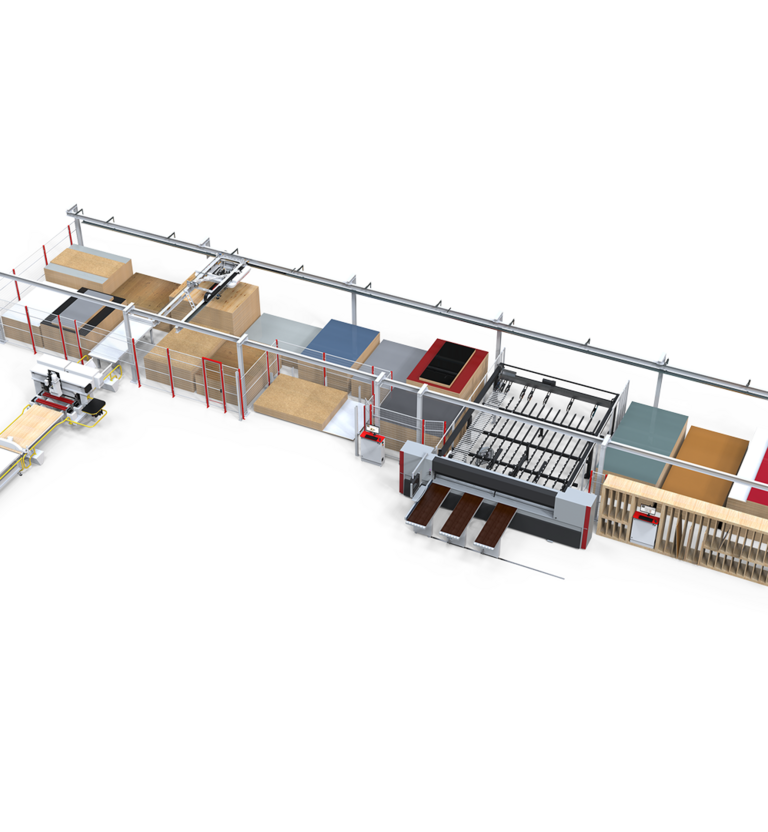

Barbaric's storage systems enable automatic storage of panel material with maximum efficiency and also allow fully automatic loading of various production lines such as saws or CNCs. From low-cost, compact solutions for production to high-performance industrial solutions as well as multi-level configurations - we offer a solution for every handling task.

Features

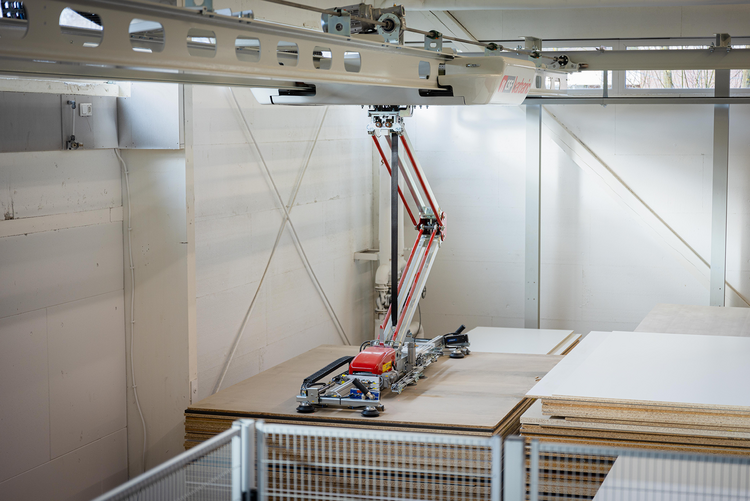

The panel storage system CSF Professional combines functionality, performance and design in one machine. With hundreds of systems installed worldwide barbaric has become a specialist in warehouse logistics and vacuum technology. For each company in the crafts, supplying or industry, we offer suitable storage solutions.

Know-how and design

CAD-optimized product design and low net weights meet the high demands of fast speed and short cycle times. Optimum use of space - only 100 mm lateral distance in all directions is required.

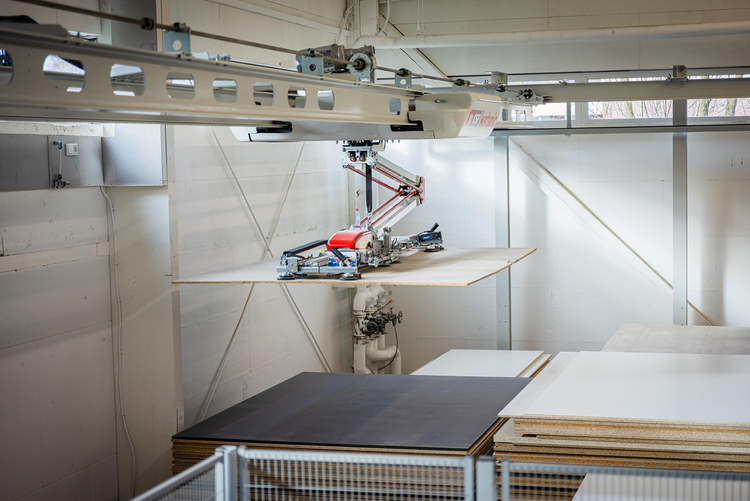

Manipulator

Unique design and narrow body. All essential functions and components are integrated. Touch screen and user control panel can be placed anywhere around the storage system.

Rotation function, panel measurement and angle correction

With the 90° rotation unit, panels can be stored in all directions. In each stacking process the panels are measured and weighed. High process reliability through continuous measuring and recording of the weight of the panels. Orientation of the angular position while driving. 180° rotation unit optional.

Your benefits at a glance

- optimized material flow

- gentle manipulation, no damaging of the panels during transport

- optimization of space

- reduced personnel expenses

- simplification and alleviation of production processes

- higher capacity utilization of your manufacturing machine

- highest flexibility in production processes

- best possible material utilization due to re-integration of rest pieces

- integrated warehouse management

- short payback periods of one to two years

- Order-picking - operation without saw is possible

Technical changes and errors excepted.

Barbaric CSF Panel Storage System & NST Nesting Picker @ Hüser Michels Carpentry

Features

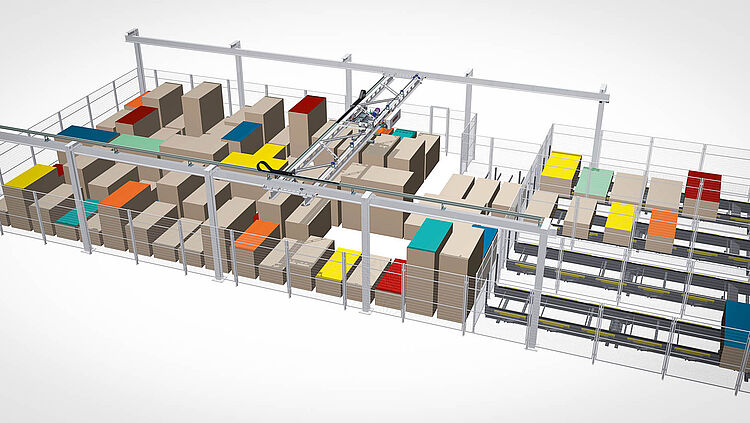

With the panel storage system CSF Industrial we can offer an individual solution for your special demands. There are no constraints on your wishes. Renowned industrial enterprises count on the stability and reliability of Barbaric systems.

Performance for industrial producers

Our panel storage system CSF Industrial meets the high industrial demands for functionality and performance.

- cycle times below 1 minute

- movement speeds up to 150 m/min

- crane bridge lengths up to 25 m

- integration of chain conveyors or

- conveyor belts

Technical changes and errors excepted.

Your benefits at a glance

- extremely large storage areas possible (up to 25 m x 70 m)

- optimized material flow

- gentle manipulation, no damaging of the panels during transport

- optimization of space

- reduced personnel expenses

- simplification and alleviation of production processes

- high transportation services

- highest machine availability

- highest flexibility in production processes

- significant increase in productivity

Features

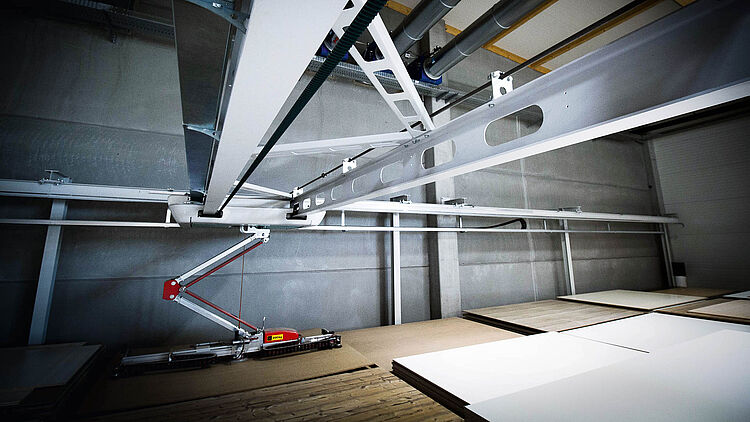

Multilevel storage systems offer the maximum efficiency for customers with high production halls. With the CSF Multilevel Barbaric offers the possibility to store boards on the upper floor and to feed the processing machines at ground level. For particularly high performance and storage capacity even multiple storage manipulators can be implemented one above the other. An optimal solution for high-performance industrial plants.

A highlight – our double-scissor load arm

The construction in a double-scissor configuration offers many advantages:

- Lifting height of 4200 mm

- Optimal storage efficiency through storage in upper level

- Flexibility in space configuration

- Adequate height of lower level with 3200 mm

Technical changes and errors excepted.

Your benefits at a glance

- Efficient height use of your production hall

- Often no need for production hall expansion (enormous cost savings)

- Sufficient and comfortable ground level height

- Access to upper level through maintenance stairs

- Installation of dust extraction or supply lines on steel construction possible

- Optimal material flow

- Gentle and damage-free material handling

- Optimal storage capacity

- Camera system for optimal surveillance from user terminal

Customer installation at Tischlerei Wegerer GmbH

Barbaric Panel Storage System CSF & LPS Labeling Printer

Barbaric CSF Multilevel

Labeling printer LPS

The Labeling Printer LPS perfectly completes Barbaric's range of products in the field of panel handling and offers an optimal extension of our storage or feeding systems for part cutting. With this unit, boards can be labelled even before they are cut to size. Manual labelling after cutting and problems with part identification are now a thing of the past.

Case studies

Ideas that move!

Learn more about our realized customer projects.

Our sales team is there for you!

If you have any questions or would like a quote, please contact us.

Phone: +43 732 779800

Email: sales-automatic@barbaric.at

After-Sales-Service

We are there for you - even years after the sale.

In order to ensure that our handling systems function optimally, we rely on good cooperation with our customers and particularly customer-oriented support through our competent service team.

Our products

Manual vacuum lifters from Barbaric enable efficient handling of heavy wood and glass panels and save valuable time in production. While conventional manipulation by hand requires 2-3 employees, a vacuum lifting systems allows a single employee to move oversized panels with maximum ergonomics and without physical exertion.

Product overview Manual lifters

Our automatic handling solutions take over fully automated process steps in wood panel and part production. Panel storage and retrieval systems, feeding systems, buffer storage and return systems are just a few examples of modern systems in the field of material handling. All of our machines are built individually according to the requirements of our customers, while proven handling concepts and trusted components are used.