Your Partner in Material Handling

Innovative Handling Solutions by Barbaric

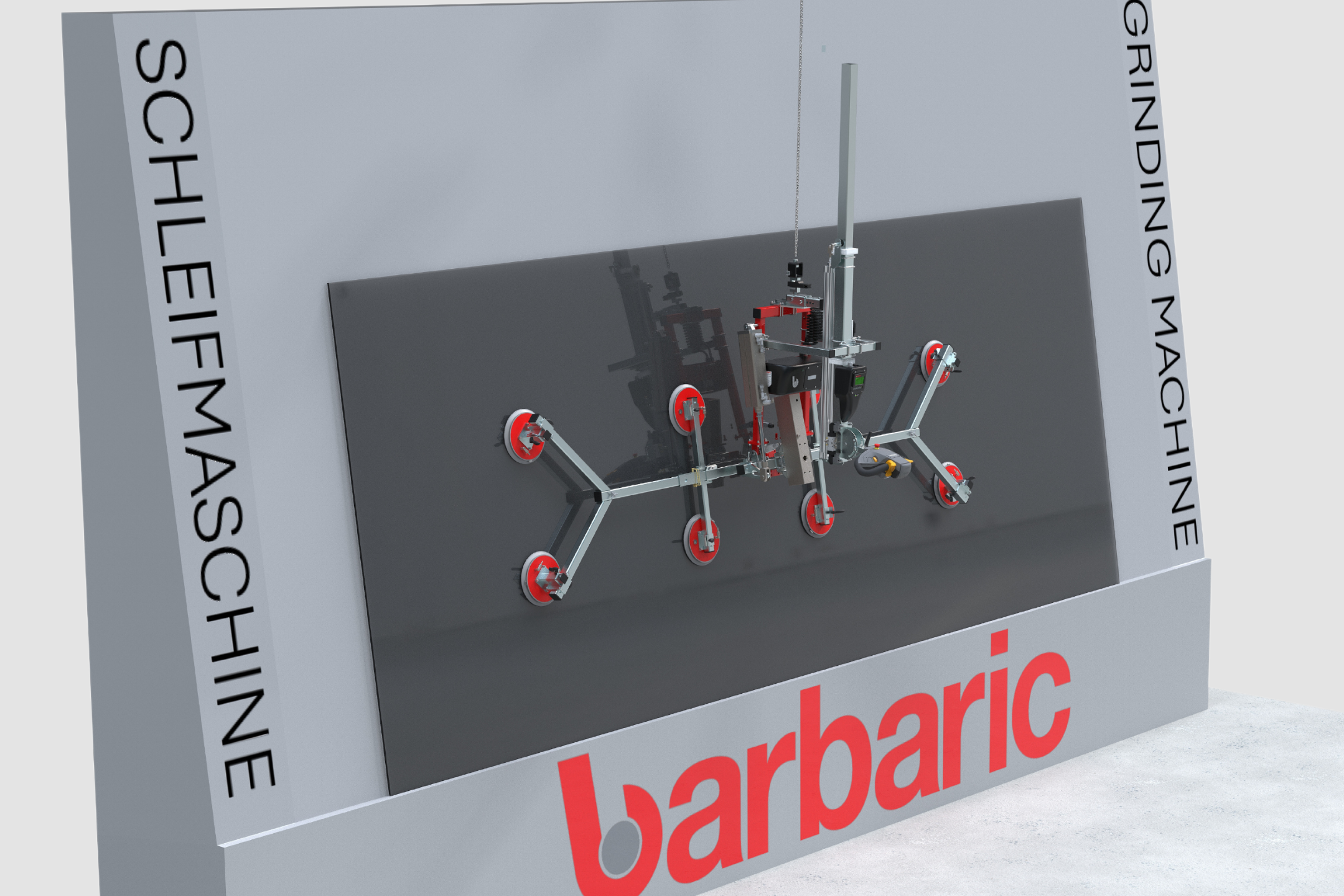

From manual vacuum lifters for glass and wood to fully automatic Panel Storage and Retrieval Systems for wooden panels, we provide the perfect solution for every handling task. Our versatile material handling solutions are designed not only for panel materials but also for furniture parts and various other materials, ensuring they can be fully automated for stacking and manipulation.

Barbaric manual vacuum lifters enable the efficient handling of heavy panels, saving valuable production time. Unlike traditional manual handling, which requires two or even three employees, our vacuum lifting system allows a single employee to move oversized panels effortlessly and ergonomically.

Our automation solutions take over the entire handling process in panel and parts manufacturing. Panel Storage and Retrieval Systems, Feeding Systems, Buffer Storage System, and Return systems are just a few examples of our state-of-the-art material handling equipment. Each system is custom-built to meet our clients' specific needs, utilizing proven components and concepts to deliver optimal performance.

Our subsidiary based in Wake Forest, NC

Located in Wake Forest, NC, Barbaric North America Inc. is the dedicated subsidiary of Barbaric, delivering cutting-edge material handling technology to customers across the United States, Canada, and Mexico.

From our Wake Forest office, we provide direct sales support for both automation solutions and vacuum lifters with crane systems. Our on-site project management team ensures a seamless process for complex handling solutions—from order placement and shipment to installation, commissioning, and final handover to the customer.

For vacuum lifting systems, we maintain a fully stocked warehouse with our best-selling lifters, enabling fast delivery for the most common wood and glass handling applications.

NOW HIRING

Installation Technician

For Automatic Handling Systems in North America

Key Responsibilities:

- Perform mechanical and electrical installation of cutting-edge automatic handling systems.

- Independently manage on-site assembly and commissioning throughout North America.

- Conduct service visits, troubleshoot issues, and provide maintenance for existing customer installations.

- Offer independent telephone support and remote troubleshooting assistance.

A Look Back at IWF 2024

The International Woodworking Fair (IWF) 2024 in Atlanta once again proved to be a key event for the wood and furniture industry, bringing together over 1,000 exhibitors from around the world. The trade show provided an invaluable platform for showcasing cutting-edge innovations, live product demonstrations, and industry networking.

At our Barbaric booth, visitors experienced firsthand the capabilities of our CSF storage and retrieval system, designed to handle laminated boards, MDF, and textured or non-flat surfaces, including interior and exterior doors with cut-outs. In addition, we showcased a wide range of our best-selling vacuum lifters for panel and solid wood materials, with a special focus on the versatile UWL 3—the ultimate solution for ergonomic and effortless panel handling.

Overall, IWF 2024 was a resounding success, offering valuable insights into the future of wood processing and strengthening connections within the industry. We look forward to continuing these conversations and pushing the boundaries of material handling innovation!

Welcome, Mike Schwartz!

We are excited to welcome industry expert Mike Schwartz to the Barbaric North America team as our new Project Manager for Automatic Handling Systems.

In his role, Mike will work closely with direct customers and distribution partners across the U.S. and Canada, focusing on:

- Panel Storage and Retrieval Systems

- Return Systems for Edge Banding Machines

- Automated Loading & Feeding Solutions

With extensive experience in the material handling industry, Mike brings valuable expertise and technical knowledge to our team. After an intensive training week at Barbaric HQ in Austria, he is now ready to support our customers with tailored automation solutions.

We’re thrilled to have Mike on board and look forward to the impact he will make at Barbaric North America!

Contact Mike:

E-Mail: mschwartz@barbaric.us

Phone: +1-984-327-8804

Our new building!

We’re excited to announce that Barbaric North America has officially moved into our new office and warehouse! The build-out of our new facility is now complete, providing us with expanded space to support our continued growth in the coming years.

Our new location allows us to enhance operations, improve service, and stock more products, ensuring faster delivery times and even better support for our customers across North America.

Our new address:

Barbaric North America Inc.

741 Merritt Capital Drive, Suite 117

Wake Forest, NC 27587, USA

Ryan Beaster is our US sales representative for manual lifting systems. He presents our RWL RackLifter at Ligna 2023 in Hannover.

Our Showroom in Wake Forest, NC

Experience our innovation live!

Batch Size One Production

Barbaric RTS + IMA Novimat Compact

With this production line Barbaric and IMA Schelling offer batch size one production at an attractive price point with no compromises on quality. Through scanning the parts at the edgebander the system gets all required information for fully automated production and material handling. The Barbaric RTS 02 Return System features a stacking function, making it possible to stack finished parts for transport or even load parts from a previously prepared stack.

Fully automatic feeding

Barbaric LCV + Schelling fh5

With this production line Barbaric and IMA Schelling offer a saw with automatic material handling solution for maximum efficiency and quality. A Barbaric LCV feeding system allows fast and easy feeding of your manufacturing machine at a minimal cost. Other customer benefits include low space requirement and the physical relief of production workers.

We are here for you!

Direct communication is very important to us.

Our team from Barbaric North America is there for our customers within the US, Canada or Mexico!

E-Mail: info@barbaric.us

Phone: +1-919-425-2803

Barbaric North America Inc.

741 Merritt Capital Drive, Suite 117

Wake Forest, NC 27587, USA

Handling Solutions from Austria

The product world of Barbaric

Barbaric stands for quality "Made in Austria".

Barbaric GmbH was founded in 1995 by Stefan Barbaric and has been the first point of contact for sophisticated handling technology ever since. Our ultimate goal is to support our customers through custom-made handling solutions for wood and glass.

Through years of innovation and the use of state-of-the-art components, Barbaric is able to implement ergonomic systems with high profitability and short payback periods. System solutions for complex manufacturing processes are always developed and implemented in close cooperation with the customer.

Barbaric is on the cutting edge and continues to evolve through innovation. The Austrian family-run business quickly develops into an internationally renowned company with currently around 100 employees. Accompanying the rapid development, the company is also honoured several times with awards and prizes.

Planning & Construction

From planning to implementation.

All of our machines are special constructions that are individually adapted to your needs. We take over the complete solution: starting with conception and 3D-planning, adaptation of our machine to your production processes up to the precise manufacturing of your individual machine.

Production & Installation

With quality and competence.

With our production facilities based in Austria we highly focus on quality, constant innovation and professional competence in the production of your handling system. On-site at the customer our installation technicians guarantee a professional assembly and the punctual startup of your machine.

After-Sales-Services

For longevity and reliability.

We are there for you - even after the sale. No matter what - spare parts, maintenance or technical support - our team of service technicians is at your disposal to guarantee the function and optimal performance of your system even years after startup and installation.

News

Construction progress on the office building at the Eidenberg site